Most of the world's sugar is made from sugar cane...specifically from the juices that are in the cane itself. We don't grow a lot of sugar cane but we have clumps here and there at False Bluff for casual use...for instance, as a snack. Also a clump of sugar cane makes for an interesting landscape accent.

A piece of cane is cut and then peeled and chewed. The stuff is very fibrous so the cut piece of cane is chewed to release the juice...and it is its own handle.

Some years ago we built a rudimentary press for extracting the juice. Reducing small quantities provides a really nice syrup. (A photo of our press is below.)

Reducing large quantities of sugar cane gives the world sugar. All kinds of sugar including: turbinado, muscovado, panela, jaggery, and that white stuff you buy at places like Walmart or even Whole Foods (unless you're in San Francisco).

Regardless of the name of the sugar and regardless of the processing method it's all sucrose - some types more pure than others. Although it all comes from some degree of reduction, the processing involved in whatever reduction technique is used will determine the name of the type of sugar you end up with. (Reduction is all about removing the liquid from the juice.)

There's a spectrum - like making white bread in which the flour is bleached, then processed to remove all the good things that nature gave it...and after all this some vitamin and minerals are added to the bread to give it 'natural goodness.' It's still bread. Sort of.

During the harvest season I buy molded 'bricks' of locally made sugar to take back to Virginia. I'm pretty careful about wrapping it before I pack it, usually using a waxy paper and lots of tape. The stuff makes wonderful gifts...partly because it's unusual but mostly because it's delicious. Some of the gifts have been used in baking, mostly cookies; but some have simply disappeared a pinch-sized bite at a time. The stuff seems to last until it's used or consumed - as long as it's kept dry.

Planting sugar cane could hardly be easier the way we do it. I'm sure the planting is much more complicated when hundreds of acres is involved. Canes are cut...removed from the roots by slicing near or at the ground. The leaves are stripped off and then the canes are cut again...into pieces about 18 inches long. A shallow trench is dug, the cane pieces are dropped into the trench and then covered. New canes, looking like stalks of grass, appear in a couple of weeks...and then it grows until it's harvested and the process begins again.

This is our very simple - almost primitive - but very efficient cane press in action.

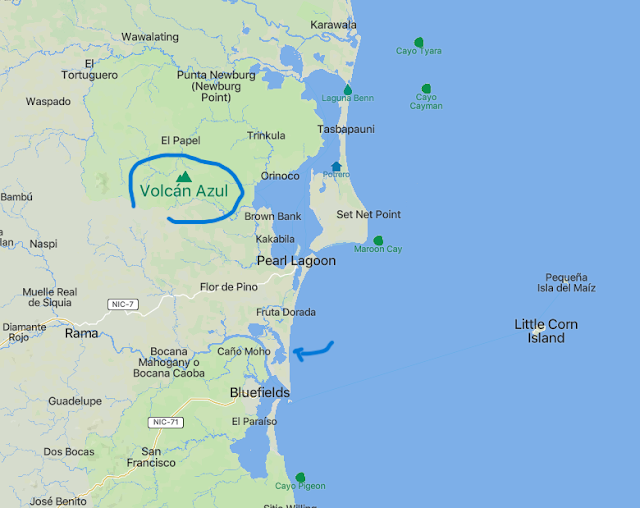

In Bluefields some local farmers use all or some of their sugar cane harvest to...make sugar...in bricks or lumps the same size and general shape as bricks as I mentioned above. But I still don't know the official name of the kind of sugar they make, only that it's very good. People with much more sugar cane than we have press their harvest in some manner probably more sophisticated than ours.

The juice is then boiled until it has become a thick syrup which will solidify after it's removed from the fire. This syrup is poured into molds of some sort...the molds in my area producing brick-shaped blocks of pure raw organic cane sugar. The color of the sugar bricks varies depending on who's making them. I've brought home both dark and light colored sugar and can't taste much difference:

People who can't buy this sugar in Bluefields can buy something like it online. In fact an eight ounce cone-shaped product, described as panela (one of the types listed here), can be purchased for just a bit more than $9.

The bricks I buy at sidewalk markets in Bluefields weigh about a pound each and sell for $2.

What's left of the sugar canes themselves after harvest is called bagasse and can be used for all sorts of other things including fuel for power production - like running a generator; or for making paper and cardboard. But the part of sugar cane most people are familiar with is the juice that's processed in lots of ways to produce many types of sugar.

.png)

.png)

.png)

.png)

.png)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

%20(1).png)

.jpg)

.png)

.png)

.png)

.png)

.JPG)